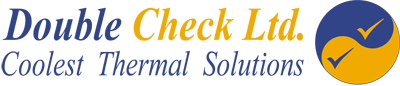

A Vapor Chamber (VC) is a planar heat pipe, that spread heat in two dimensions. VC is typically used when high heat fluxes are applied to a relatively small evaporator area. During operation, the heat input into the evaporator vaporizes liquid within the evaporator wick. The vapor then flows throughout the vapor core space, creating an isothermal heat spreading. The vapor then condenses on the condenser surfaces, where the heat is rejected by air or liquid cooling. Capillary forces in the wick then return the condensate to the evaporator. Most VCs are capable to operate against gravity at wide range of inclinations.

Actually, VC operates as heat flux transformer, adsorbing a high heat flux from an electronic chip or laser diode, and transforming it to a lower heat flux that can be rejected by natural or forced convection.

VC can be made from different metal including copper, aluminum, stainless steel and others. A wide range of working liquid can be used depending of the working temperature range and case material

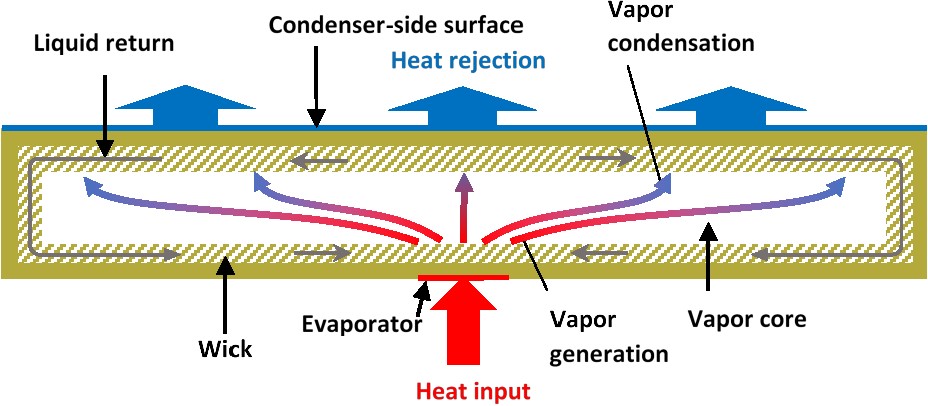

Contact us

Loop heat pipes

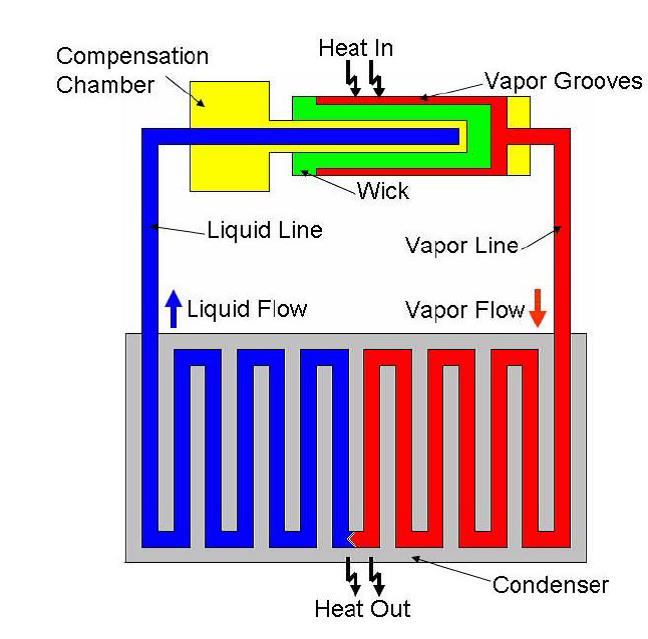

Loop heat pipes (LHPs) belong to two-phase heat-transfer devices that operate on the closed evaporation – condensation cycle, in which capillary forces are used for the pumping of a working fluid. LHPs possess all the main advantages of conventional heat pipes, but owing to the original design and special properties of the capillary structure (wick) are capable of transferring heat efficiently for distances up to several meters at any orientation in the gravity field, or to several tens of meters in a horizontal position or in the conditions of zero gravity. Besides, the LHP conception allows a wide variety of different design embodiments, which essentially extends the sphere of functional possibilities and practical application of these devices.

Heat Pipes

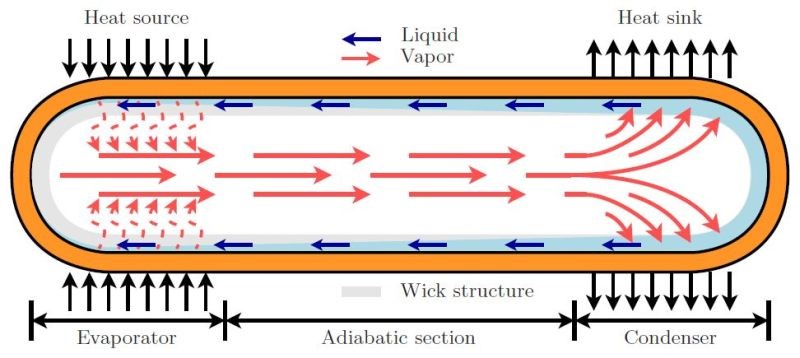

The best solution for isothermal heat transfer is to utilize a Heat Pipe. Heat Pipes have an inherent thermal conductivity which, if properly designed, can reach more than 1000 times that of copper the same size. A Heat Pipe consists of a vacuumed sealed metal case whose inner surfaces are made of a capillary wick structure. Inside there is a small quantity of working liquid, under its own pressure, that enters the pores of the capillary material, wetting internal surfaces. Applying heat at any point along the surface of the Heat Pipe causes the liquid to boil and enter a vapor state. The liquid picks up the latent heat of vaporization. Vapor, having a higher pressure, moves inside the sealed container to a colder location where it condenses. Thus, the vapor gives up the latent heat of vaporization and moves heat from the input to the output end of the Heat Pipe. Due to highly efficient heat transfer by phase transformation, heat fluxes inside a Heat Pipe are considerable and temperature gradients are very small.

In themselves, Heat Pipes do not function as heat sinks or cold plates. They can be part of a complete cooling solution, whereas the Heat Pipe is designed to move the heat efficiently from the heat-generating device to another location where an air or liquid stream can take the heat away. Heat Pipes can be designed and manufactured in various shapes and sizes to fit the customer’s specific needs and requirements. Heat Pipe case can be made from different metals including copper, aluminum, stainless steel and others. Working liquid is chose depending on the working temperature range and case material.